Automatic Packaging Tightness Testing Machine DVACI Model CDV4 BT AVVI

Manufacturer: DVACI – Mexico

Origin: Mexico

Contact Us

Mô tả

Thông số kĩ thuật

Phụ kiện

Tài liệu đính kèm

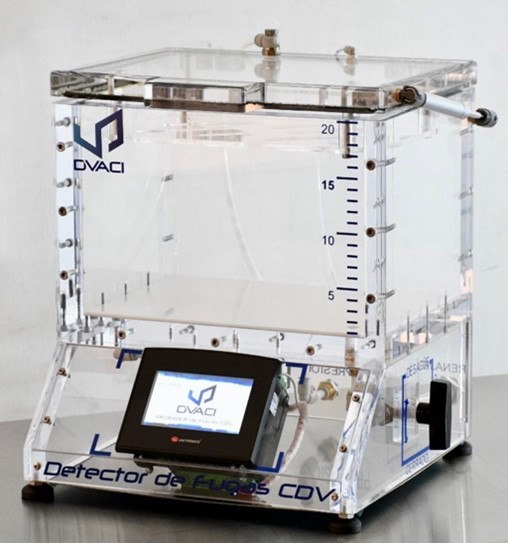

DVACI Automatic Packaging Tightness Testing Machine Model CDV4 BT AVVI is the 3rd model in Series CDV BT AVVI. CDV4 BT AVVI with desktop design, convenient and compact, is a specialized packaging tightness testing solution to test the tightness (gas leak) of bags, bottles, tubes, cans , effective packaging for food and pharmaceutical products.

Featured Specifications Fitness Tester Automatic Packaging DVACI Model CDV4 BT AVVI:

- Inside size: 500 x 350 x 350 (mm); 20” x 14” x 14” (in)

- Total size: 580 x 500 x 560 (mm); 23” x 20” x 22” (in)

- Weight: 50 kg

- Maximum pressure: 900 – Mbar

Features of Model DVACI CDV4 BT AVVI:

– Design modern, handy and compact desktop

– Intuitive and easy operation.

– Touch screen (Requires password input when logging in, allows to create a working program)

– Components from famous international brands

– Produced in modular assemblies for easy maintenance

– Under-chamber control system (save space)

– There is drainage underneath after completing the test

– The lid is designed to be safe, easy to operate (with lifting post and hinge)

– The lid has no warning sensors to help avoid damaging collision

– Height-adjustable stand

– Rounded edges for easy cleaning

– Gradometer (allows water level determination for immersion tests)

– Allows the option to add a set of needles to test vacuum packed goods

– Allows option to print results (with built-in printer)

Controller:

– Touch screen automatically controls preset working time and pressure parameters

– Allows access to up to 15 different user information with different password protection

– Allows testing process with 2 working features as follows:

+ Quick Test Feature: Allows users to quickly set pressure productivity and working time right on the main screen

+ Programmable Recipes Feature: Allows preset 16 programs work differently

| Model | CDV4 BT AVVI |

| Inner Dimensions | 500 x 350 x 350 (mm)

20”x 14” x 14” (in) |

| Total size | 580 x 500 x 560 (mm)

23” x 20” x 22” (in) |

| Weight | 50 kg |

| Maximum pressure | 900 – Mbar |

| Working methods | Visual |

| Setting pressure unit | InHg, mmHg, mbar |

| Working scale of pressure transducer | Type of piezoelectric transducer 0 to -1 bar |

| Warranty Policy | 1 year |

| Vacuum source | Venturi (You can choose the compressed air source at the factory or use a vacuum pump) |

| Required compressed air source | From 4 to 5 bar |

| Pressure and time controllers | Full auto |

| Material | PMMA (Polymethyl methacrylate) |

| Power supply | 110 VAC, 220 VAC |

| Gateway: | Connect to compressed air source via port Æ8

Connect to the water supply via port Æ12 |

| Standards-compliant device | ASTM D3078, ASTM D6653, ASTM D4991, ASTM D5094, ASTM D4169, ASTM F2096 |

Optional Accessories

1/ Result printer

2/ Vacuum packed sample needle set

Catalog Automatic Packaging Tightness Testing Machine DVACI Model CDV4 BT AVVI

Leave your questions, we will answer them right away

EN

EN VN

VN