What is Autoclave Sterilizer or Autoclave Sterilizer? How are they built and how to use them? This is a very familiar device in laboratories, factories as well as medical facilities. However, have you fully understood the functions and applications of this device? If you are still struggling in the process of learning about this steamer with many uses and benefits, the following article is for you.

1. What is Sterilization? Commonly used sterilization methods

Sterilization (also known as sterilization), is a term used a lot in medicine. It is understood as a process that destroys all microorganisms, bacteria, viruses or any other life forms that exist on the surface of the object to be sterilized.

In the world today, there are many different sterilization methods, the most popular of which are: heat sterilization, steam sterilization and pasteurization.

Heat sterilized

This is the method commonly used in hospitals, clinics or medical centers. This method uses maintaining high temperature to kill harmful bacteria, viruses and microorganisms on the surface of the object to be sterilized. The ideal temperature to perform this method usually ranges from 150 degrees Celsius to 250 degrees Celsius in a few hours. This is considered a fairly popular method today due to its convenience and ease of implementation.

Pasteur paste

this method does not kill all living organisms on the sterilized surface, it only inhibits only slow down their growth. This can also be seen as a rather peaceful method.

Pasteur pasteurization is quite suitable when sterilization is required during the production of fresh milk. In addition, sterilization methods using chemicals, plasma or radiation are also quite popular methods.

Steam Sterilization

Steam sterilization is a method that utilizes saturated steam at high pressure and temperature to create compression , increase impact and impact, thereby helping to destroy bacteria, viruses and microorganisms on the surface of the sterilized object. This is also the method commonly used on autoclaves.

Steam sterilization is also a method with outstanding advantages compared to the above methods and is used in laboratories, hospitals or medical facilities,… So specifically, what is this autoclave possessing many preeminent uses?

2. What is Autoclave?

Autoclave is a device used to Disinfect items such as surgical instruments, equipment, medical instruments, or laboratory supplies. In fact, this autoclave is like a giant pressure cooker, using the power of steam to destroy all microorganisms or germs left after the items to be disinfected have been washed. with boiling water or detergent.

3. Working principle

Microorganisms, spores or bacteria cannot be completely destroyed by steaming or boiling at 100 °C. Therefore, there is a need for a more effective sterilization method to ensure that all microorganisms, spores or bacteria are destroyed on the object to be disinfected.

Working principle of autoclave: when heating, the autoclave will close the valves and create high pressure in the autoclave chamber, changing the boiling point and evaporation of the water (normally boiling and evaporating at 100°C) to the set temperature (usually 121°C), which in turn creates saturated steam in the autoclave for sterilization.

According to research, sterilized at a temperature of about 121°C, for a period of 15 – 20 minutes, microorganisms Bacteria and microorganisms will be completely destroyed by the effects of saturated steam under high pressure.

4. Uses of autoclave sterilization

As mentioned above, autoclave usually Used to disinfect items and tools in medical facilities, laboratories, or in microbiological culture environments. This device is used in many fields, including medical, microbiological, pharmaceutical and industrial.

Some applications include:

- Disinfect medical equipment, supplies and instruments such as needles, scissors, scalpels, sutures,… or some tools that can other reuse. Disable chemicals, potentially dangerous substances such as pathogens, viruses, microorganisms,… before being discharged into the outside environment.

- Sterilize equipment and instruments in the laboratory, in microbiological culture,…

- Creating the right temperature and pressure environment for growing quartz crystals in the electronics industry.

- Composite treatment when vulcanizing rubber in industry.

- Sterilize packaging during food donation.

Refer to the video on the use of sterilization packaging of ALP autoclaves:

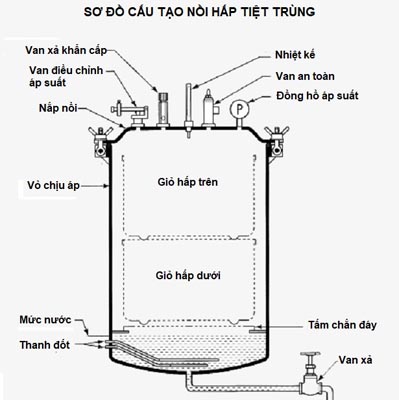

5. Structure of autoclave

A steamer can be divided into 5 main parts:

– Sterilization chamber: Usually made of stainless steel material, helping to ensure sustainability and long-term use in humid environment, high temperature and pressure for the autoclave. This part of the chamber is usually cylindrical in shape and can withstand great pressure during use.

– Pressure air duct system: This system controls the temperature and pressure inside the autoclave , usually made up of copper tubes and solenoid valves.

– Heating system: Made from heat-insulated incandescent, the outer layer is chrome-plated copper or stainless steel, helping to maintain the temperature of the autoclave.

– Circuit system: Includes power, display, control boards,… to help connect sets parts of the autoclave together, make sure they work properly.

– Safety system: Includes a system of sensors for temperature, pressure, water level,…

6. Regulations on allowed conditions to use autoclaves

– Establishments and businesses need depending on their professional needs and require functional units to perform effectively. Calibrate the autoclave heat points. Perform temperature calibration for autoclave to determine their temperature error.

– Establishments and businesses that use autoclave need to apply GMP production process – Is a practical standard used in production to ensure stable quality, meet registered standards and safe hygiene conditions during production.

– The person assigned to operate the autoclave needs to meet the following criteria: normal health; aged 18 years and older; mastering expertise and profession; pass the rigorous examination and test as prescribed by law; be granted a group 3 occupational safety card by the owner of the business establishment or enterprise; assigned written tasks on operation of pressure vessels and boilers; participate in training courses on occupational health and safety held annually in accordance with the law.

7. How to use autoclave

Here are instructions for use autoclave:

– Step 1: Fill the steam chamber with clean water.

– Step 2: Place the item to be sterilized in the mesh basket inside the autoclave

– Step 3: Make sure to cover the pot tightly, then start selecting the right functions for each type Samples to be sterilized, depending on quantity and size. These functions include

- Sterilizing temperature and pressure

- Steaming time

- Drying time

– Step 4: Check and close the exhaust valve, exhaust valve before operation

– Step 5: Click Start to start the autoclave

– Step 6: Once the temperature has reached the right level, the Autoclave will automatically start calculating the sterilization time

– Step 7: After the sterilization process is completed, proceed to drying

– Step 8: After sterilization is completed, the autoclave will sound and the indicator light will light up. In case if the light is not on, you need to turn off the On/Off switch and then turn it back on

– Step 9: Press the Emergency button to release all the pressure in the pot. You are only allowed to remove the item to be sterilized when the pressure gauge is zero.

A small note when you want to continue using the autoclave to disinfect and further dry other items, open the lid autoclave, let the machine cool down for about 20-25 minutes, then turn it off and on again to reset the system.

8. Place to buy a reputable autoclave

You can see the importance and great benefits an autoclave can bring. The implementation of autoclaving, sterilization in industry, medical or microbiological environments, … if not done by a quality autoclave, will leave many unpredictable consequences.

Co.,Ltd Hiep Phat Equipment specializes in importing and distributing distributes laboratory equipment products from famous brands in the world. At Hiep Phat, customers can find many types of autoclave with various models, sizes, capacities and functions.

Also Hiep Phat also provides services check, replace components and repair Autoclave:

Several product lines provided by Hiep Phat:

8.1 ALP CLG Series Autoclave

Autoclave sterilizer ALP – CLG series is the most advanced line of ALP Autoclaves, using LCD screen with many functions and ensuring safety for users. use.

Outstanding features of ALP CLG series Autoclave:

- Steam Release Pressure Pulse (SFPP)

- Multi-program compatible

- Combines parts that are susceptible to damage over time

- Quality fast cooling fan

- Liquid Crystal Interactive Display

- Data logging system (Optional)

- IQ/OQ profile conforms to GMP, GLP standards

8.2 Autoclave ALP – CL Series

Steamer ALP – CL series is commonly used in laboratories of Food, Cosmetics, Schools, or in the field of pharmaceutical processing…. The autoclave possesses many features and uses, ensuring safety during use such as: Quick lid lock, easy opening and closing, with locking latch; The lid of the pot locks securely while in operation, can only be opened when the pot temperature drops to < 80°C and when the pressure gauge reads 0. Electromechanical locking system helps to lock the lid in case of power failure, avoiding user contact with dirty tools that have not been sterilized.

See more product lines ALP autoclave.

Hopefully the above article has helped you better understand the autoclave. If you are looking to buy autoclave products, or have any questions in the process of using all kinds of products device lab, don’t hesitate to contact Hiep Phat qua Hotline: (028) 6287 4765 or Email: sales@ thietbihiepphat.com to receive timely advice.

Autoclave Sterilizer

Leave your questions, we will answer them right away

EN

EN VN

VN